So I have come up with the following approach.

1. Clean silicone contamination as best as I can.

2. Sand off bilge paint (trying not to contaminate underlying FG)

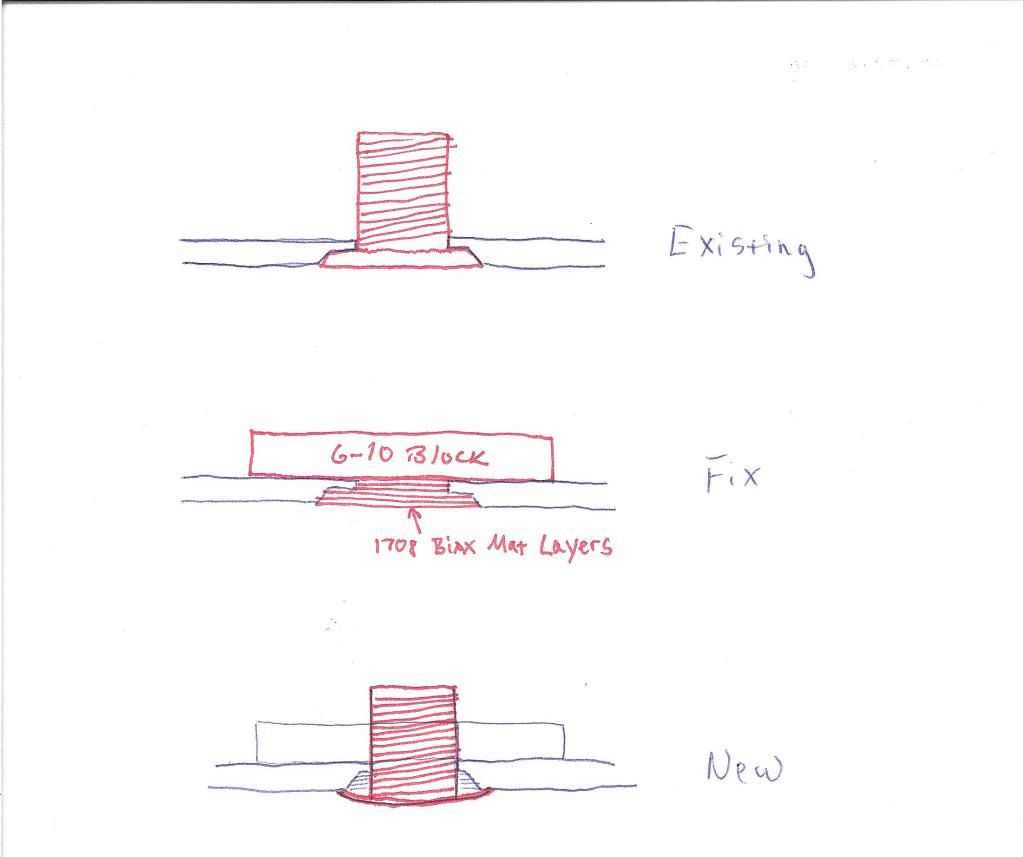

3. Epoxy G10 backing block in place over open hole

4. When backing block is cured, drill 1/4 inch guide hole in center

5. Place circular layers of 1708 and build up flush with hull.

6. Sand and fair flush with hull

7. Barrier coat

7. Redrill guide hole from inside of boat.

8. Using guide hole as center, drill new transducer hole through layers of 1708 and backing block.

9. Install transducer

I figure if the backing block does not bond too well it wont be the end of the world as the sealant and pressure of the thru hull should keep it together.

Does this sound OK? Will this give me enough strength around the existing hole? Or is there some other method I should consider?

Thanks!

Doug