As usual, my ongoing, never-ending work on my sailboat consists of one step forward, half a step back.

So yesterday I very easily - almost too easily - pulled the prop off the shaft, pulled the shaft and stuffing box out of the stern tube and pulled out the cutless bearing. Easy peasy.

So today I took the stuffing box apart and went at taking the prop shaft coupling off the end of the shaft, so I can clean it all up (it was pretty rusty).

The square-head set screw on the side of the coupling was so rusty it snapped off when I twisted it with a wrench.

I drilled out the center of the set screw, so that I would at least be able to get the coupling off the shaft.

That coupling was STUCK. Long story short, I used up probably half a cylinder of MAPP gas heating it up, half a can of Kroil, and I managed to snap off one of the arms of one of my gear pullers (well, it is a cheapo Taiwanese one from Horror Freight, so no big surprise there - and no big loss either).

Once I had the coupling off, I went to use the next size drill to slightly enlarge the hole I had drilled through the broken set screw, so I could extract the remains of the screw and clean up the threads in the hole. The drill, of course, snapped off in the hole. And, of course, it's a cobalt drill.

Further efforts at removing the firmly wedged, broken off tip of the cobalt drill resulted in another snapped-off tip of a smaller cobalt drill being lodged firmly right beside it.

Yes, go ahead, I hear the snickering now.

SO.

I'm thinking the hell with it, I'll just leave them in there, and drill a new hole, 90 degrees away from the old one, tap it and stick a new set screw in there.

Any reason why not to do that and buy a new prop shaft coupler instead? I've found a couple sources for them, but I'd just rather not spend another $70 if I don't have to.

Any reason why not to do this? Prop shaft coupler.

-

ILikeRust

- Skilled Systems Installer

- Posts: 285

- Joined: Tue Oct 19, 2010 8:22 pm

- Boat Name: Grizabella

- Boat Type: Pearson Wanderer 30

- Location: Richmond, VA

Any reason why not to do this? Prop shaft coupler.

Bill T.

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

-

Paulus

- Skilled Systems Installer

- Posts: 199

- Joined: Mon Nov 22, 2010 12:05 pm

- Boat Name: Guillemot

- Boat Type: Mariner Ketch

Re: Any reason why not to do this? Prop shaft coupler.

I admit, I snickered a bit, but then, afraid I would jinx my next project through the wrath of the project Gods, I quickly regained composure...

As regards the coupler, I would try like heck to save the old one - without pictures its hard to evaluate options on how to get the cobalt bits out of there, but it shouldn't need that much effort to push them up out from the inside if out have room...

Drilling with the second bit would have worked if you tried with an outy one - they sell drills that rotate the other way, which when they grab, tend to jam the "right way", i.e. counter to the way the original bit jammed and often it pulls the old bit (or stuck bolt) out..

I say let's see a pic and I am sure others will chime in with much better advice than what I gave...

As regards the coupler, I would try like heck to save the old one - without pictures its hard to evaluate options on how to get the cobalt bits out of there, but it shouldn't need that much effort to push them up out from the inside if out have room...

Drilling with the second bit would have worked if you tried with an outy one - they sell drills that rotate the other way, which when they grab, tend to jam the "right way", i.e. counter to the way the original bit jammed and often it pulls the old bit (or stuck bolt) out..

I say let's see a pic and I am sure others will chime in with much better advice than what I gave...

-

ILikeRust

- Skilled Systems Installer

- Posts: 285

- Joined: Tue Oct 19, 2010 8:22 pm

- Boat Name: Grizabella

- Boat Type: Pearson Wanderer 30

- Location: Richmond, VA

Re: Any reason why not to do this? Prop shaft coupler.

Well I posted the same question over at the Wooden Boat forum and a guy over there who's a naval architect and probably has forgotten more about boats than I'll ever know informed me it's a very bad idea to re-used the old coupling, particularly if it was rusty when pulled off. The issue is that it's meant to be a precision, interference fit and pressed on to the prop shaft. When you get the old, rusty one off, the inside of the coupling bore flakes off some rust and will never again have the precise fit it's supposed to have. Once you've cleaned it up, if it just slides right on (which it probably will, having lost a couple thousandths of metal due to rust), it's trash.

Check out this video.

Check out this video.

Bill T.

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

-

Paulus

- Skilled Systems Installer

- Posts: 199

- Joined: Mon Nov 22, 2010 12:05 pm

- Boat Name: Guillemot

- Boat Type: Mariner Ketch

Re: Any reason why not to do this? Prop shaft coupler.

Well.... does it? After you clean it up, how's the fit?if it just slides right on (which it probably will, having lost a couple thousandths of metal due to rust), it's trash.

Whoever made that video obviously sells that stuff.

A lot of forums, including this one, has people that are quick to recommend the ultimate - perhaps beacuse they "ultimately" don't have to pay for it... Too often, in my huble opinion, many far less expensive options are available - no guaranteed outcome, but even with new stuff, there still is no guarantee that it will all work.

I thought that is what these forums are for - to learn from each other and find out alternate ways to get stuff done, without the obvious recommendation to "buy new".

I tend to wait until I have convinced myself that I need to solve something with my wallet - I am quite pragmatic when it comes to working on things that I own, using the family kitty.

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

Re: Any reason why not to do this? Prop shaft coupler.

Straight couplings are and should always be a light press fit. If they just slide on this a bad situation waiting to happen.. A previously rusted coupling will almost never have the proper fit when re-installed. I think I have seen all of about two that were able to be re-used safely over the last 25 years or so. My friend has a shafting shop so I have seen my fair share of botched DIY couplings that have been re-used and caused isues. Couplings are cheap compared to a ruined shaft or a lost shaft. The new coupling should also be fitted and faced by a shafting shop that does good work. Between coupling and fitting & facing you should be under $100.00 at a reputable shop.

When you replace it consider a split coupling. Walter's Machine and Buck Algonquin both make them.

When you replace it consider a split coupling. Walter's Machine and Buck Algonquin both make them.

-

ILikeRust

- Skilled Systems Installer

- Posts: 285

- Joined: Tue Oct 19, 2010 8:22 pm

- Boat Name: Grizabella

- Boat Type: Pearson Wanderer 30

- Location: Richmond, VA

Re: Any reason why not to do this? Prop shaft coupler.

One of the guys at the Wooden Boat Forum also recommended a split coupling. What's the advantage?

Bill T.

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

Richmond, VA

"All men dream: but not equally. Those who dream by night in the dusty recesses of their minds wake in the day to find that it was vanity: but the dreamers of the day are dangerous men, for they may act their dreams with open eyes, to make it possible." - T E Lawrence

-

Quetzalsailor

- Master of the Arcane

- Posts: 1100

- Joined: Fri Aug 26, 2005 9:53 am

- Boat Name: Quetzal

- Boat Type: LeComte North East 38

- Location: Philadelphia, PA

Re: Any reason why not to do this? Prop shaft coupler.

I posted a sob story like this a couple years ago. My fitout from hell!

I cut that shaft out, replaced the coupling. Used the split coupler. The 4 1/2" dia x 1/16" thick cutoff wheels from the Despot work wonderfully fast, chucked up in your angle grinder.

Don't leave a mess to remind you of your poor luck or to tell the next owner about yourself that you wouldn't want known. I once had a Volvo which was owned by someone who had access to an endless supply of some sort of sticky black sealant; whenever, wherever he needed or lost a fastening there was a gob of that stuff. I learned to disassemble and fix anything that had that stuff on it because I could be sure something was wrongly assembled.

I cut that shaft out, replaced the coupling. Used the split coupler. The 4 1/2" dia x 1/16" thick cutoff wheels from the Despot work wonderfully fast, chucked up in your angle grinder.

Don't leave a mess to remind you of your poor luck or to tell the next owner about yourself that you wouldn't want known. I once had a Volvo which was owned by someone who had access to an endless supply of some sort of sticky black sealant; whenever, wherever he needed or lost a fastening there was a gob of that stuff. I learned to disassemble and fix anything that had that stuff on it because I could be sure something was wrongly assembled.

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

Re: Any reason why not to do this? Prop shaft coupler.

ILikeRust wrote:One of the guys at the Wooden Boat Forum also recommended a split coupling. What's the advantage?

The split coupling is:

1- More secure and offers less chance for damage to the shaft & key. A loose coupling can shear a shaft just like a loose prop can.

2- Is usually easier to remove as there is only about 3/4"-1" max of solid, un-split coupling rather than 4" plus.

3- Has a slight chance of actually being re-used because it can be tightened onto the shaft. However, this is not a guarantee and before re-using any coupling it should be taken to a reputable shafting shop for examination and a fit check and & re-facing.

Fitting & Facing A Coupling - What The Heck Is That??

Posted this a few weeks ago on another forum.

I am currently doing a shaft, cutlass, coupling and alignment job and when I arrived at my buddies shop the other day the job was not yet done. Actually, it was very good because he allowed me to make a short video of how facing a coupling is actually done.

Here's the video: Facing A Marine Shaft Coupling (LINK)

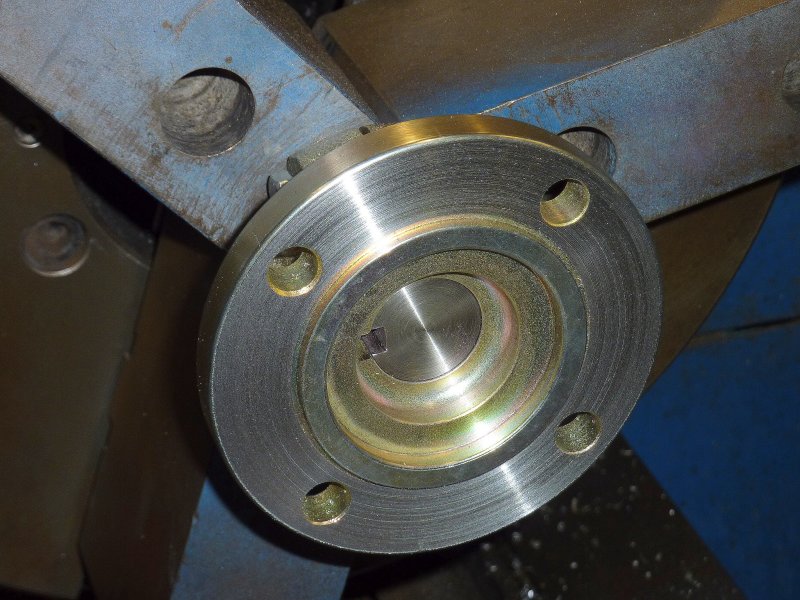

Faced:

So what is "fitting & facing".

Fitting: To fit a straight or split coupling to the shaft for an interference fit. Good shops will usually strive for lighter than a bearing press fit but more than what you can slide on easily by hand.

Before you can face the coupling you first need to fit the new coupling to the new shaft or old shaft. Rusted old couplings can rarely, if ever, be re-used due to loss in tolerance from the layer of rust broken free during removal.

Sailboat couplings from reputable manufacturers such as Buck Algonquin & Walters usually always ship a little under sized so that they can be "fitted" to the shaft and not be loose. Even though it was a split coupling it still requires fitting and facing. My shafting shop is VERY picky. This fit is most always a light tap fit meaning you need often need to tap the coupling on with a wood or lead mallet.

The proper fit of the coupling to the shaft is critical, especially with straight couplings, but even with split couplings. If the fit is sloppy it will work the set screw holes, and the key, if the draw bolts come loose, and in a worst case a shaft can pull out of the coupling. A more likely scenario is that both become ruined from slop movement and in extreme cases the key works the shaft so much that it fails. This failure is often right at the end of the keyway. A loose prop can do the same.

Fitting is often done by hand with the aid of a machine shop lathe to hold the coupling. The reaming tool for this is very precise and they are quite expensive. It is used for the rough fitting. The coupling is most often inserted into the head of the lathe and the reaming tool end centered so the reamer goes in perfectly straight. The machinist makes a couple of turns of the reamer with a wrench and then removes the coupling and test fits it. This rough fit can usually be done in two or three tries. This one took three fittings. Care is taken to not to go to big because you can never make the hole smaller. Multiple fittings is usually the reality. This one took about 12-15 minutes to fit to the shaft.

Because this was a split coupling it was shimmed square to maintain the "fit" all the way through. The shimming was measured as accurately as possible before hand reaming.

The reamer is then adjusted by hand and inserted & centered into the coupling. It is then turned by hand with a wrench. After a couple of turns it is removed and the fit is checked. If not good this is repeated.

A good final fitting requires a lead mallet to tap the coupling onto the shaft.

Once it is fitted the coupling is installed on the shaft, with key or without, does not really matter, and with the set screws in place and is then ready for facing.

Facing: This makes the flange face rotate perfectly square to the shaft with no wobble.

Facing is rather easy compared to fitting and the video can be seen above. If you listen carefully you can hear the woo, wooo, wo as it is ground. The noise is not smooth because the cutting head was taking more in some areas and less in others due to wobble in the flange face.

Shaft flanges are aligned to roughly .001" for every inch of coupling diameter. Thus, a 4" coupling should be aligned to somewhere between .003" & .004". If the face is out .001" - .003" because it was not faced this can get inaccurate and a become a bear to align.

Gear box flanges are faced at the factory to spin true. Provided you have not bent it through pounding on it, or using it to press off a coupling, it should be darn close to rotating true. Unless your coupling is like new, with no rust between it and the shaft, I don't advise pressing the coupling off the shaft with it. Some gear boxes, like the small Hurth's (HBW-50 etc.), have very flimsy output shafts and they can easily fracture or be bent. It doe not take much to achieve a .003" or greater bend in a gear box coupling.

Often times with old shafts the easiest way to remove the coupling is to cut the shaft. This 1987 shaft had bad cutlass wear as well as bad stuffing box wear, and the coupling was not coming off in the boat any other way due to very limited access. A new shaft & coupling is far less costly than ruining your gear box!!

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

Re: Any reason why not to do this? Prop shaft coupler.

Paulus wrote:

Whoever made that video obviously sells that stuff.

Well, I made that video and I have nothing at all to do with selling that stuff at all. I just repair it and have seen shafting failures quite often when DIY's and even some "pro's" try to re-use a coupling. The key and set screws are not intended to take 100% the working loads on a solid coupling.

Some of us are quick to recommend the "ultimate", or more accurately the proper procedure, because cutting corners on some areas of boat repair can end with catastrophic results. The failure modes most often result is a lot more expense than the recommendation of doing it correctly the first time.Paulus wrote:A lot of forums, including this one, has people that are quick to recommend the ultimate - perhaps beacuse they "ultimately" don't have to pay for it... Too often, in my huble opinion, many far less expensive options are available - no guaranteed outcome, but even with new stuff, there still is no guarantee that it will all work.

This was caused by a loose coupling because it was installed incorrectly, re-used and ultimately resulted in the key taking the entire load and causing the shafting to fracture. The same thing can happen with a loose or incorrectly installed prop. While this sort of failure is less common in small HP engines the act of hitting a pot buoy or floating line can also result in this type of outcome even on small engines. The correct fit of a straight coupling to the shaft is rather important and in the whole scheme of boat ownership is one of the less expensive fixes...