Zach, here are some of my thoughts, slightly rambling because I'm under the weather and my head is foggy. This is from a background of heating land-structures with woodstoves up in northern Minnesota.

Edit stuck in to say that I thought about this more, and realize that you weren't exactly proposing to cool the pipe, and it kind of sounds like I thought you were. Actually, double pipe is often used to insulate the pipe and keep it hot inside and cool outside (like in an attic, where there's insulation between the two pipes structure; or in a heated room, where if you have a low clearance situation you can buy double metal pipe that's not insulated between)

Now back to my previous diatribe:

I don't think there's anything wrong with a hot flue. When burning wood (not saying you'll be doing this, but if you are), it's actually desirable, because it keeps creosote from forming inside the chimney (which can catch on fire and cause a chimney fire - those are scary). When you have a home woodstove, you're always endeavoring to keep the chimney or flue-pipe nice and hot. Not ridiculously hot, of course, but the last thing you want to do is "cool" the flue. One gadget that's handy for getting a feel for temps is something they make for metal stove pipes which is a magnetic thermometer. Very inexpensive and shows you what's going on (I suppose these days you could use an infrafred thermometer, but these are handy and simple and just sit there working all the time.)

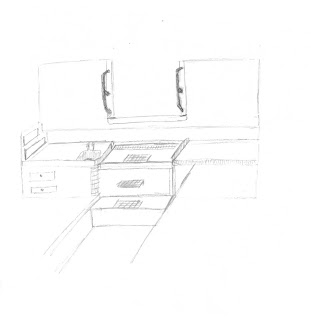

What keeps the whole thing safe is a proper installation. That is, it should be installed in such a way that you don't have to worry if the flue gets hot (normally hot, anyway). In houses you achieve this mostly with air space, especially behind a suspended shield (i.e. metal sheet that's held 1" off the bulkhead, or the like). In home installations with metal pipe, there's a big, bulky, sheet metal fitting that carries the pipe through the rafters and roof safely, with lots of air space. There are similar things for boats, often with a well that's meant to have water in it. You can see lots about this at the oft-mentioned

www.marinestove.com They have installation diagrams, etc. It's also important to keep the flue as small in diameter as the mfgr. recommends, because a larger flue will allow cooling and also compromise the draft.

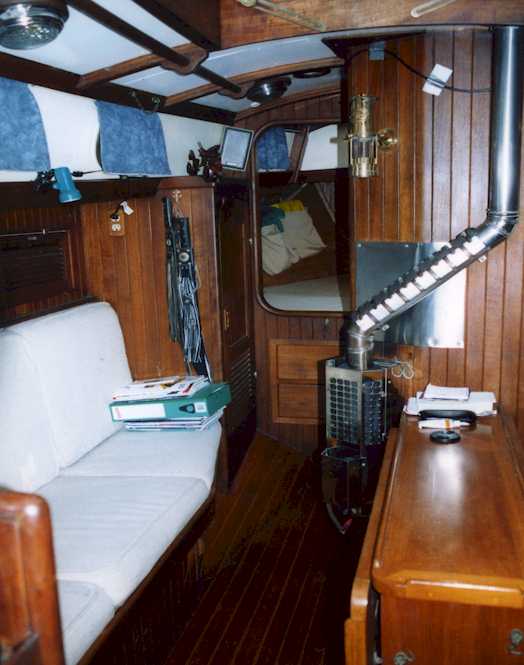

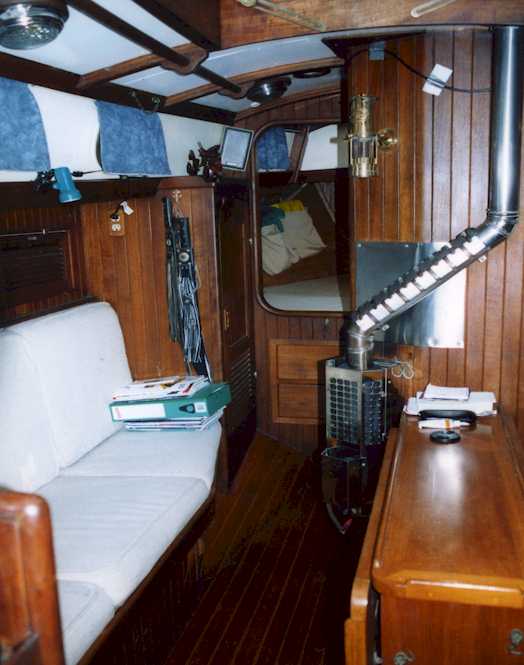

I don't believe diesel heaters get quite as hot as solid fuel, but the principles are similar. When I was in Northern British Columbia for a season, we had a Sigmar diesel heater (a fine unit) mounted on a bulkhead and ran it about 16 hours a day (always on except when sleeping). This was on a 10' beam 30-footer. I didn't install the stove, but it seemed like a mostly-good installation and we never had any overheating of the boat parts that I detected.

That said, I would have added more heat shielding of the bulkhead wood, were it my boat, especially in that little gap above the stove body, and then again on the upper bulkhead. Although the charring of the wood you see is from a previous owner's woodstove installation. The thing is that if wood gets really hot, over and over, it lowers the burn point, and then it can catch fire much more easily than it would have to begin with. We did have some metal heat shielding on the bulkhead behind the stove (this came with the stove, I think), and also behind the stovepipe (purpose fit). The stove was mounted near the sole, so no overhead protection was necessary. The through-deck fitting was not the water ring type.

There was also some perforated metal shielding around the flue pipe lower down, so that if you touched it you weren't touching super hot pipe. I'll put in a couple of photos that show it to some extent.

So I guess if it were me, I'd be thinking about installing in such a way that the flue can safely get reasonably hot, more than trying to keep the flue cool.

Nothing like a cozy boat with a heater going! :)