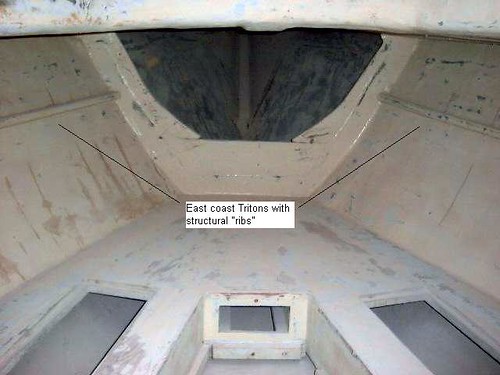

I have always heard the folk lore of how Tritons are built like battle ships. Tim produced strong evidence to back it up (see picture below) on his well known website.

NTA website proclaims:

West Coast Tritons - An owner of a 1963 West Coast Triton in Seattle says, "The Triton was built by both Pearson in Rhode Island and Aeromarine Plastics in Sausalito, California. Very early Pearsons had some problems with balsa core an other minor items. 'West Coast Tritons' were built like battleships."

"In the early '60's Aeromarine built some 125 boats. They're easily distinguished from their East Coast cousins. East Coast boats have wooden coamings and wooden trim. The California built boats are all plastic. Ralph Beauregard, long time owner and racer of #150, Rascal II flat out claims, 'West coast boats are built better than East Coast. The Sausalito bunch were much better boat builders than Pearson ever was. West Coast boats have no balsa in the decks. None. They're pure glass.' "

Well, I have always taken this information for granted. So three years ago when I put in the through hull in the original hanging locker to convert it to a washing sink I was quite surprised that the skin of the hull is only about 1/4" so thick. I thought it must be this location that is unusual for whatever reason and that other area skins will be thicker.

Well yesterday, I cut out the original head through hulls (two of them). And imagine my surprise when I found that the hull in those locations is also only 1/4" thick. But that is not all. I had to replace knot meter transducer (the free rotating wheel that sends speed data to the display) yesterday. The through hull is located in the bilge about a foot or so below sole level on starboard side). Guess what, the skin is also about 1/4" thick! Now I am not sure any more about my Triton 106 being built like a battle ship. I always heard on this forum that no two Tritons are identical. I would not think that this applies to the laminating schedule too. Does the thin skin on Triton 106 reflect the difference between east and west coast Triton or is it just Triton106? I guess the more critical question is whether 1/4" is really safe outside protected water? Will it survive a collision with a submerged log?

Thanks and best regards,