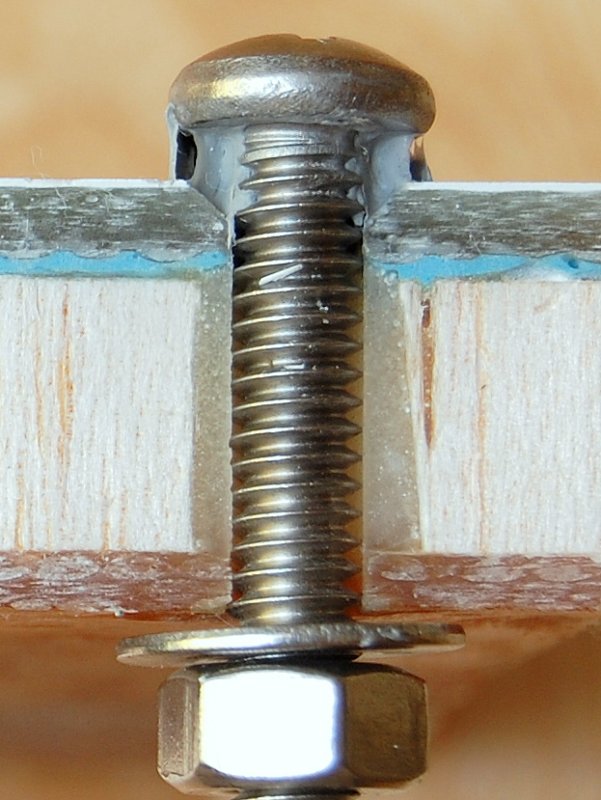

For years I have been trying to describe, as have others, in words, how to "pot" or fill deck hardware penetrations with thickened epoxy to seal the decks core from further moisture damage.

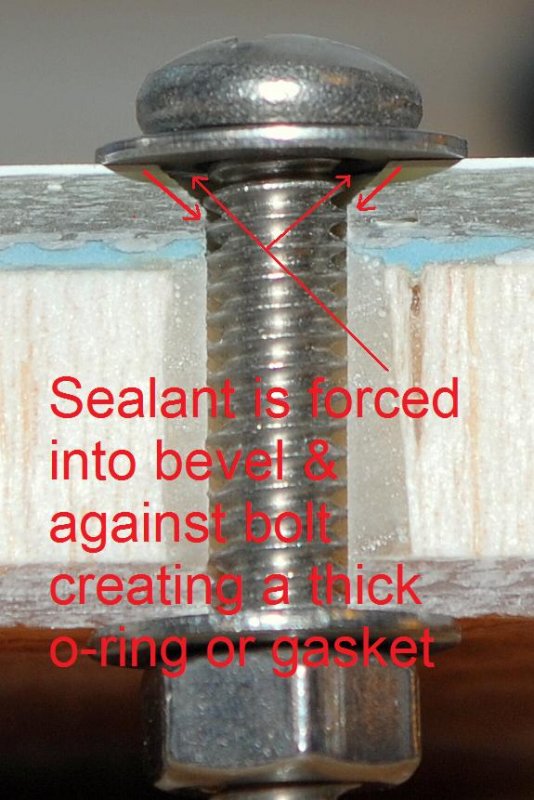

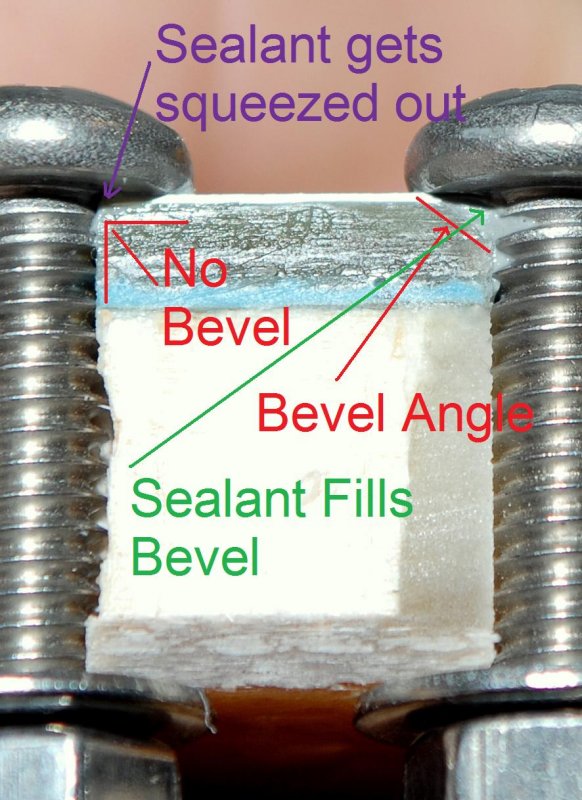

I have also been trying to describe why a slight bevel to each hole that penetrates the deck is a good idea. Sometimes folks understand it via words, and sometimes they don't.

I have had this article on my mind for years and finally over the last month or so had the chance to make it all happen with some late nights in the barn.

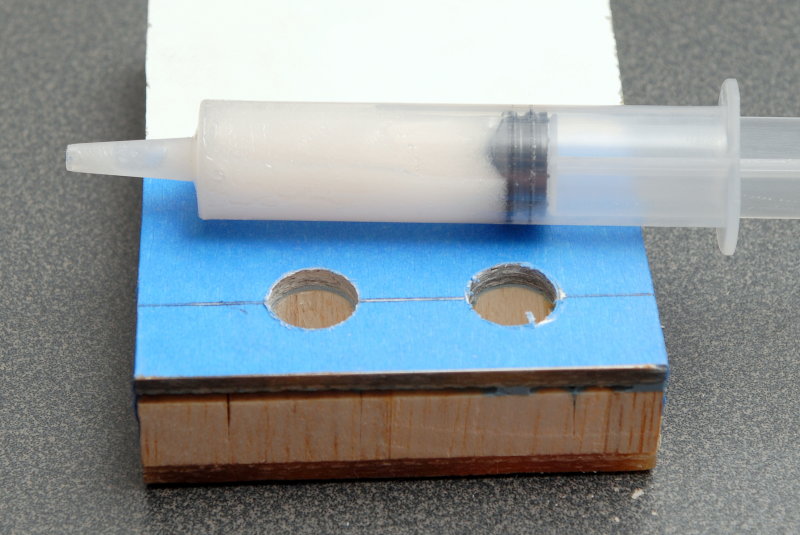

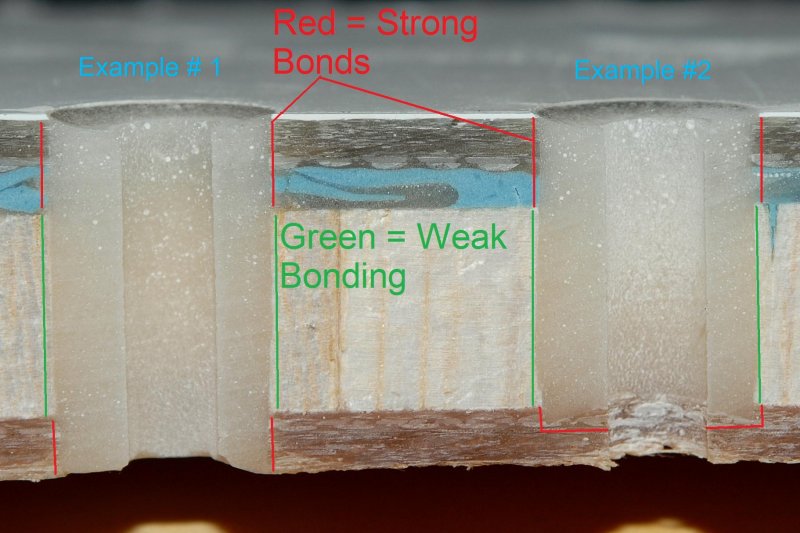

As far as I know this is the only article of it's type that uses deck lamination cut-a-way samples to show what goes on inside the deck when you "pot" with epoxy and countersink the bolt holes..

Of course, on this site, most of you guys have your decks torn up and thus have the luxury of doing a fill of a larger area or laying in some G-10.

I hope this helps make some sense of something that really isn't all that difficult to tackle just difficult to describe..

If you see any typos, and I'm sure you will, please let me know and I'll fix them as soon as I can. I'm not a writer, but do have a lot of tricks & techniques I've learned over my years of boating that I like to share with fellow boaters. Some of these I feel can best be illustrated through pictures, with the help of some words of course..

Click this to read it:

http://www.pbase.com/mainecruising/sealing_the_deck

And some of the photos from the article;