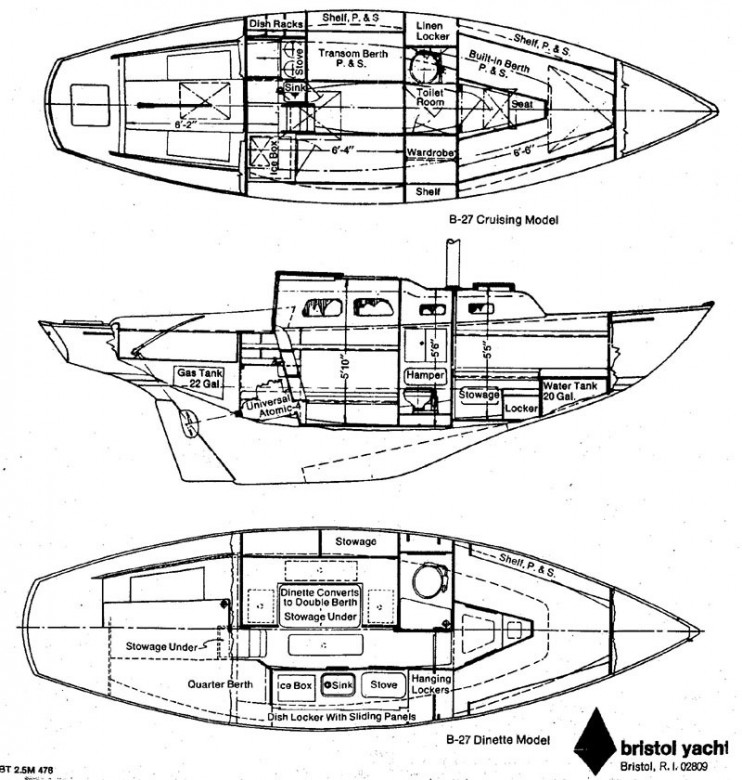

I'm steadily making progress on the full restoration of my Bristol 27, but before I fully build out the interior, I've been considering adding some fore-to-aft stringers in the boat. I may be using the term "stringer" wrong here, but in my mind, I consider a stringer as a forward to aft reinforcement, fiberglassed directly to the hull which will add add strength and resist torsion of the hull. Below is an image of the stringers I plan to add (the stringer locations are in red):

To further assist, I've broken down my current thinking and questions below. If you'd like to add some input, feel free to address the specific questions I've posited and/or add comments to anything I'm not considering.

+ What material should I use for the stringers?

-> I've heard that one can use halved PVC, foam, wood or even halved garden hose. My issue with the hose or PVC is that there would be a gap inside that could possibly trap water. Since these stringers will likely be installed below a layer of insulation, there won't be an opportunity to drain any condensated water. Adding wood would seam quite heavy, so maybe foam is the best choice? If so, what type of foam?

+ Should I drill through already installed bulkheads in an effort to span stringers between bulkheads?

-> I've read the most effective stringers run all the way from forward to aft. However, it would seem to me that adding them between the major bulkheads in the boat would also add a significant amount of strength and I don't really want to drill through bulkheads to run these stringers if it's not necessary.

+ How important is it to add these stringers?

-> I'm really trying to go all out for strength on this boat. I'd like to go to northern latitudes where ice may be an issue. Obviously I'm not trying to winter over or anything with a fiberglass boat, but I want to build the strongest boat possible.

A few more notes about this plan...

+ I won't be able to install stringers between the mast-head bulkheads (the head compartment and icebox area), because I've already completed major construction in these areas; meaning I have insulation already installed and no clear access to the hull to install stringers. That being said, these areas are quite reinforced already so I'm not too-too worried.

+ I would add more stringers, however things like the settee tops, interior bulkheads and shelves will act as stringers as well. So, the stringers have been placed only in areas where there will be large "panels" of fiberglass.

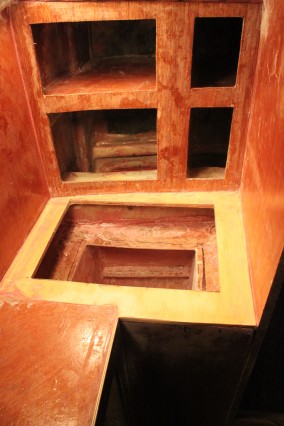

+ If you'd like to get a more full idea of how the interior is constructed at this time, see the images below which start at the forward chain locker and move through the boat all the way to the lazarette (or visit my project site - http://www.bristol27.com):

Chain locker

Forward v-berth w/ kerosene tank installed

Aft v-berth, area where water tanks will be placed

Cockpit bulkhead and battery compartments/lockers

Port sea locker

Ok, thank so much for everyone's input and please let me know if I can clarify anything.Lazarette locker w/ yet to be installed "splitter bulkheads"