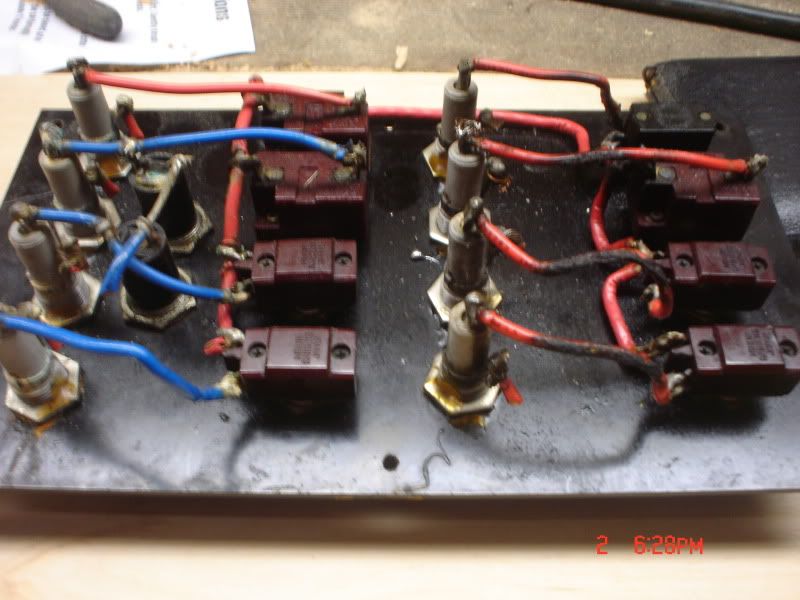

I removed the panel and took it home to see if I could re-arrange, or add, some switches... Upon closer examination, I decided it needed replacement. Note the charred lines at some of the switches... my son thinks this may be from a lightning hit... ( the switches in question all power stuff up the main mast) - I on the other hand am hoping that whoever put this together used a torch to do the soldering and had, errrr..., bad aim...

Either way, I decided to make a new little panel with some extra switches....

In keeping with the classic look of the boat - everything being made of wood, I decided to see if I could make a panel from oak...

Turned out pretty nice - I will have four additional switches, plus I decided to put a designated LED to show power at the panel - mainly to remind me to throw the main switch before I leave the boat (frequently forgotten last season)...

While at it, I also changed the H2O and Propane indicator lights to LEDs - too bad all I could get my hands on were amber - I may change the panel Power LED to green once I can find one.

This is still the rough panel, fitted with the hardware to make sure it fits and makes sense. The camera seems to distort the edges - it is a perfect rectangle ;>)

Now, for this learned group - is there any objection or consideration for using wood for a panel? Of course, this little panel will be stained, sealed and varnished before it is finally mounted in place of the old one, but before I go nuts making it pretty and fit it, I figured I would run it by here... I do have a fresh piece of black 1/4" acrylic I could fit into what would then be a frame - much like the old panel - but I kind of like this look...

Anyone?