Proper seacocks

-

George ( C&C 40 )

- Skilled Systems Installer

- Posts: 254

- Joined: Thu Jan 06, 2005 12:39 pm

- Location: Williamsburg, VA

Proper seacocks

Hi Tim,

I still have a few old style bronze gate valve through-hulls in "low clearance" spots in the bilge of my C&C 40. They still work fine but it would be nice to have a real ball valve unit versus the gate valve. ( it would make winterizing the engine easier for one thing ) Is there a proper type of right angle fitting I can screw down on the existing through hull so I can eliminate the gate valve and install a ball valve? - something that would pass muster with a marine surveyor? I've got maybe 5 or 6 inches of vertical clearance to work with so the new ball valve is going to have to be parallel with the hull.

George

I still have a few old style bronze gate valve through-hulls in "low clearance" spots in the bilge of my C&C 40. They still work fine but it would be nice to have a real ball valve unit versus the gate valve. ( it would make winterizing the engine easier for one thing ) Is there a proper type of right angle fitting I can screw down on the existing through hull so I can eliminate the gate valve and install a ball valve? - something that would pass muster with a marine surveyor? I've got maybe 5 or 6 inches of vertical clearance to work with so the new ball valve is going to have to be parallel with the hull.

George

- Tim

- Shipwright Extraordinaire

- Posts: 5708

- Joined: Tue Apr 01, 2003 6:39 pm

- Boat Name: Glissando

- Boat Type: Pearson Triton

- Location: Whitefield, ME

- Contact:

There's no specific rule, regulation, or requirement governing this sort of thing. Most surveyors like to see through hulls that are threaded into flanged, bolted sea valves, but there is no requirement that the valve be of this type. Sea valves, or seacocks, can be either of the ball valve variety, or a rotating cylinder, or tapered plug. Straight ball valves without flanges are certainly more reliable and easier to use than gate valves, and I think replacing your remaining gate valves is a good idea regardless.

If you're not going to install a flanged sea valve that is bolted through the hull, then you can use any reasonable arrangement of quality fittings to make the connection. The main advantage of a bolted, flanged sea valve is that the installation is stronger and provides additional support, mainly when torquing the handle--particularly if the fitting is stiff. In ordinary circumstances, the additional support probably isn't strictly needed. However, with the clearance you're talking about finding a throughbolted, flanged sea valve may be a challenge, unless the fitting size is small (3/4", say).

Beware that most through hull fitting threads are likely to be straight thread, not tapered; a lot of the standard pipe fittings have tapered threads and won't thread down sufficiently before binding. This may make your installation more of a challenge than you hoped for! I've seen a lot of straight ball valves perched on top of non-tapered threads with only a few threads truly engaged--not ideal.

Assuming you can find a straight-threaded fitting, you can use a bronze 90? directly on the through hull thread, onto which you can then thread your new ball valve. You'll need non-tapered female threads on one end, and tapered male threads on the other to fit into your straight ball valve. Obviously, the fewer fittings you can use, the stronger and more waterproof the overall setup is going to be.

I'll try and look up the applicable standards tomorrow and make sure there isn't anything important that we're overlooking here. But common sense and prudence really rule the day for something like this.

If you're not going to install a flanged sea valve that is bolted through the hull, then you can use any reasonable arrangement of quality fittings to make the connection. The main advantage of a bolted, flanged sea valve is that the installation is stronger and provides additional support, mainly when torquing the handle--particularly if the fitting is stiff. In ordinary circumstances, the additional support probably isn't strictly needed. However, with the clearance you're talking about finding a throughbolted, flanged sea valve may be a challenge, unless the fitting size is small (3/4", say).

Beware that most through hull fitting threads are likely to be straight thread, not tapered; a lot of the standard pipe fittings have tapered threads and won't thread down sufficiently before binding. This may make your installation more of a challenge than you hoped for! I've seen a lot of straight ball valves perched on top of non-tapered threads with only a few threads truly engaged--not ideal.

Assuming you can find a straight-threaded fitting, you can use a bronze 90? directly on the through hull thread, onto which you can then thread your new ball valve. You'll need non-tapered female threads on one end, and tapered male threads on the other to fit into your straight ball valve. Obviously, the fewer fittings you can use, the stronger and more waterproof the overall setup is going to be.

I'll try and look up the applicable standards tomorrow and make sure there isn't anything important that we're overlooking here. But common sense and prudence really rule the day for something like this.

---------------------------------------------------

Forum Founder--No Longer Participating

Forum Founder--No Longer Participating

George,

Will this fit in your limited headroom? They aren't bronze but they might fit.

http://www.forespar.com/onlineCatalog/4 ... 2006.shtml

Dan

Will this fit in your limited headroom? They aren't bronze but they might fit.

http://www.forespar.com/onlineCatalog/4 ... 2006.shtml

Dan

-

George ( C&C 40 )

- Skilled Systems Installer

- Posts: 254

- Joined: Thu Jan 06, 2005 12:39 pm

- Location: Williamsburg, VA

Hi Dan and Tim,

Thanks for the notes guys. I'm going to take some more exacting measurements. It appears that I'm going to have to address each gate valve on an individual basis as each one has a slightly different amount of headroom to work with. A couple of the small ones might just work with the Forespar unit you have linked Dan. I'd like that as it is a traditional seacockand is still 90 degrees. The bigger ones might require Tim's methods. We will see.

Thanks again,

George

Thanks for the notes guys. I'm going to take some more exacting measurements. It appears that I'm going to have to address each gate valve on an individual basis as each one has a slightly different amount of headroom to work with. A couple of the small ones might just work with the Forespar unit you have linked Dan. I'd like that as it is a traditional seacockand is still 90 degrees. The bigger ones might require Tim's methods. We will see.

Thanks again,

George

- catamount

- Candidate for Boat-Obsession Medal

- Posts: 378

- Joined: Sun Jun 19, 2005 7:30 am

- Boat Name: GREYHAWK

- Boat Type: Peterson 34

- Location: Boothbay Harbor, ME

- Contact:

Tim, isn't there a guideline about your thru-hull/seacock combination being able to withstand some 500 pounds of shearing side force? I recall seeing that somewhere. I think Nigel Calder has a picture in his mechanical/eletrcial manual of his wife or somebody standing on (jumping up and down on?) a thruhull to "simulate" this test.

That said, some of the holes in my boat came with bronze thru-hulls, bronze elbows threaded onto them, then some sort of nipple (or maybe they were those elbows that have the male threads on one side, whose name I can't remember), and finally a Marelon ball valve. My surveyor was OK with this arrangement. (Other holes didn't have the elbow, which was OK, too. And a few other holes had gate valves that were seized, which was not OK...)

That said, some of the holes in my boat came with bronze thru-hulls, bronze elbows threaded onto them, then some sort of nipple (or maybe they were those elbows that have the male threads on one side, whose name I can't remember), and finally a Marelon ball valve. My surveyor was OK with this arrangement. (Other holes didn't have the elbow, which was OK, too. And a few other holes had gate valves that were seized, which was not OK...)

Tim Allen -- 1980 Peterson 34 GREYHAWK

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

-

Summersdawn

- Skilled Systems Installer

- Posts: 279

- Joined: Fri Nov 04, 2005 6:34 pm

If you are going to ask your wife to "simulate" 500 pounds force, you might want to put a retainer on a good divorce lawyer first!catamount wrote:Tim, isn't there a guideline about your thru-hull/seacock combination being able to withstand some 500 pounds of shearing side force? I recall seeing that somewhere. I think Nigel Calder has a picture in his mechanical/eletrcial manual of his wife or somebody standing on (jumping up and down on?) a thruhull to "simulate" this test.

Rick

Summer's Dawn

24 San Juan #380

Summer's Dawn

24 San Juan #380

- catamount

- Candidate for Boat-Obsession Medal

- Posts: 378

- Joined: Sun Jun 19, 2005 7:30 am

- Boat Name: GREYHAWK

- Boat Type: Peterson 34

- Location: Boothbay Harbor, ME

- Contact:

hehe, same thought occurred to me as I wrote that, so now I gotta go look it up:

Nigel Calder, Boatowner's Mechanical and Electrical Manual, third edition (2005), page 564, figure 12-46 (there was a similar figure in the 2nd edition, but I can't tell you the page number at the moment).

Shows the feet of somebody wearing Bean boots standing on a Marelon seacock mounted to board.

Caption reads:

Nigel Calder, Boatowner's Mechanical and Electrical Manual, third edition (2005), page 564, figure 12-46 (there was a similar figure in the 2nd edition, but I can't tell you the page number at the moment).

Shows the feet of somebody wearing Bean boots standing on a Marelon seacock mounted to board.

Caption reads:

Simulating a static load test in my barn (no, Terrie, my wife, does not weigh 500 pounds!).

Tim Allen -- 1980 Peterson 34 GREYHAWK

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

Harborfields Housekeeping Cottages, West Boothbay Harbor, Maine

Sailors for the Sea, a new voice for ocean conservation

-

kabauze

- Rough Carpentry Apprentice

- Posts: 59

- Joined: Sun Jan 23, 2005 11:32 pm

- Boat Name: Nevermind

- Boat Type: Pearson Triton #450

- Location: Santa Barbara, CA

- Contact:

Marelon Series 93

I used three of these Series 93 Marelon seacocks on Nevermind for the cockpit and sink drains. They are really nice seacocks and are different from and superior to the normal Marelon seacocks you find at West and the like. They are much more compact and obviously better designed. Forespar says in their literature that they are for OEM use only but I had no problem obtaining a set from Marine.com.Dan H wrote:George,

Will this fit in your limited headroom? They aren't bronze but they might fit.

http://www.forespar.com/onlineCatalog/4 ... 2006.shtml

Dan

Todd

- Tim

- Shipwright Extraordinaire

- Posts: 5708

- Joined: Tue Apr 01, 2003 6:39 pm

- Boat Name: Glissando

- Boat Type: Pearson Triton

- Location: Whitefield, ME

- Contact:

Here is some applicable information from ABYC H-27 | Seacocks, Thru-Hull Connections, and Drain Plugs.

I wouldn't call a plain old ball valve a seacock myself unless it had a flange: I'd just call it a "ball valve", but there's nothing official about either ABYC's definition or my own. However well accepted ABYC is (and rightly so), one must always remember that they have no enforcement authority. Neither do surveyors. Both hopefully offer logical, helpful, and prudent guidelines for what might be at least minimally acceptable.

Still, this a good argument for a flanged, through-bolted installation, since that would clearly resist this force more successfully, even though this standard requires nothing approaching a flanged installation or anything but something that is reasonably strong.

An improperly threaded ball valve, as I detailed in my earlier post, might be more susceptible to failure during a test like this, but even most of those would probably survive a 30-second 500 lb. static force. What it might not withstand is a shock force--something that could occur if (for example) a battery fell on it during a capsize, or someone tried to force a stuck handle with a breaker bar.

If one have a setup with properly threaded fittings and quality valves, no matter the type, it's likely to easily exceed the specifications of this standard. It's often a challenge to find truly satisfactory flanged seacocks that work in a tight space, so sometimes compromises must be made. A compromise can be OK as long as it's still strong and safe.

Based on this standard, it's pretty clear that the lower profile the fitting, the stronger it will be, all things being equal. The more moment arm you place on this force (i.e. the further away from the connection), the more susceptible to failure it woul dbe. So overlong through hulls, with excess threads passing through the hull, connected to unsupported ball valves with a long nipple on top, for example, might be logically seen as more prone to damage from a force at the end than a low-profile fitting of any type.

Note that this definition says nothing about flanges, or much of anything else, other than clearly contraindicating gate valves by defining a seacock as having a "lever type handle".ABYC H-27.4 (Definitions) wrote:Seacock: A type of valve used to control intake or discharge of water th rough the hull. It is operated by a lever type handle usually operating through a 90? arc, giving a clear indication of whether it is open or shut."

I wouldn't call a plain old ball valve a seacock myself unless it had a flange: I'd just call it a "ball valve", but there's nothing official about either ABYC's definition or my own. However well accepted ABYC is (and rightly so), one must always remember that they have no enforcement authority. Neither do surveyors. Both hopefully offer logical, helpful, and prudent guidelines for what might be at least minimally acceptable.

This certainly makes sense. The flange isn't much use if it isn't fastened to the boat, but I've seen this a lot.ABYC H-27.7.3 wrote:If a flanged seacock is used, its flange shall be securely mounted to the hull.

This sounds impressive, but really isn't if you think about it. Mostly, this standard is attempt to apply some a certain value to what should be common sense and logic, though the arrival at this value must be at least marginally arbitrary. A standard must, by definition, set a certain specification, so this seems as good as any, and completely reasonable from a strength perspective. But it isn't that challenging to meet either. Frankly, anything structural on a boat ought to be able to withstand a lot more than this. I hope that two of me and more can stand on anything important installed on my boat.ABYC H-27.7.1 wrote:A seacock shall be securely mounted so that the system will withstand a 500 pound static force applied for 30 seconds to the inboard end of its connecting fitting, at any point in its most vulnerable direction, without the system failing to perform as intended.

Still, this a good argument for a flanged, through-bolted installation, since that would clearly resist this force more successfully, even though this standard requires nothing approaching a flanged installation or anything but something that is reasonably strong.

An improperly threaded ball valve, as I detailed in my earlier post, might be more susceptible to failure during a test like this, but even most of those would probably survive a 30-second 500 lb. static force. What it might not withstand is a shock force--something that could occur if (for example) a battery fell on it during a capsize, or someone tried to force a stuck handle with a breaker bar.

If one have a setup with properly threaded fittings and quality valves, no matter the type, it's likely to easily exceed the specifications of this standard. It's often a challenge to find truly satisfactory flanged seacocks that work in a tight space, so sometimes compromises must be made. A compromise can be OK as long as it's still strong and safe.

Based on this standard, it's pretty clear that the lower profile the fitting, the stronger it will be, all things being equal. The more moment arm you place on this force (i.e. the further away from the connection), the more susceptible to failure it woul dbe. So overlong through hulls, with excess threads passing through the hull, connected to unsupported ball valves with a long nipple on top, for example, might be logically seen as more prone to damage from a force at the end than a low-profile fitting of any type.

---------------------------------------------------

Forum Founder--No Longer Participating

Forum Founder--No Longer Participating

One thing that Forespar doesn't say about their seacocks is that they can be through-bolted if you want to, but they don't mention that until you get the instructions.

I know Tim firmly believes in through-bolting and that is why I specifically asked about that before purchasing them. I was afraid of shearing off the mushroom head and have nothing holding in the seacock.

The flange, which Forespar calls the King Nut, has four holes casted in it for bolting that aren't all the way through. All you need to do is finish drilling the holes and insert the bolts.

They also say that you can cut down the through hull fitting, to fit different thickness hulls. You need at least 5 full threads of engagement for it to work at rated strength.

I have the instructions at home if you would like me to scan them and post them for you if you want.

I know Tim firmly believes in through-bolting and that is why I specifically asked about that before purchasing them. I was afraid of shearing off the mushroom head and have nothing holding in the seacock.

The flange, which Forespar calls the King Nut, has four holes casted in it for bolting that aren't all the way through. All you need to do is finish drilling the holes and insert the bolts.

They also say that you can cut down the through hull fitting, to fit different thickness hulls. You need at least 5 full threads of engagement for it to work at rated strength.

I have the instructions at home if you would like me to scan them and post them for you if you want.

-

Figment

- Damned Because It's All Connected

- Posts: 2846

- Joined: Tue Apr 08, 2003 9:32 am

- Boat Name: Triton

- Boat Type: Grand Banks 42

- Location: L.I. Sound

Re: Marelon Series 93

I'm in the middle of a rather frustrating marine.com experience with these series 93, but I've noticed that Hamilton appears to be another potential source.kabauze wrote:I used three of these Series 93 Marelon seacocks on Nevermind for the cockpit and sink drains. They are really nice seacocks and are different from and superior to the normal Marelon seacocks you find at West and the like. They are much more compact and obviously better designed. Forespar says in their literature that they are for OEM use only but I had no problem obtaining a set from Marine.com.Dan H wrote:George,

Will this fit in your limited headroom? They aren't bronze but they might fit.

http://www.forespar.com/onlineCatalog/4 ... 2006.shtml

Dan

Todd

At least one model at Hamilton

-

George ( C&C 40 )

- Skilled Systems Installer

- Posts: 254

- Joined: Thu Jan 06, 2005 12:39 pm

- Location: Williamsburg, VA

Hi Again All,

It looks like the good people at Groco have come to the rescue. I needed a couple of 1" seacocks in areas with only 6" max of vertical space. With a minimum 1/2" backing plate that gives me a max of 5.5" to work with. Groco has come out with a flanged adapter for just this type of application in their IBVF series. These adapters provide a heavy duty flanged and through-bolted attachment point for standard through-hulls and may be caped with a "street ell" into a standard in-line ball valve. All in heavy bronze. Cost for the adapter is $33 for the 1" size. The unit is fed with NPS threads to fit regular through-hulls and the output end is NPT threads to fit standard component parts. The details from Groco are here :

http://www.groco.net/CD-07/GROCO%20CAT/ ... 4-2007.htm

I haven't installed the unit yet but the estimated total height (including the handle on top of the ball valve) should be around 4.5" in the 1" size.

George

It looks like the good people at Groco have come to the rescue. I needed a couple of 1" seacocks in areas with only 6" max of vertical space. With a minimum 1/2" backing plate that gives me a max of 5.5" to work with. Groco has come out with a flanged adapter for just this type of application in their IBVF series. These adapters provide a heavy duty flanged and through-bolted attachment point for standard through-hulls and may be caped with a "street ell" into a standard in-line ball valve. All in heavy bronze. Cost for the adapter is $33 for the 1" size. The unit is fed with NPS threads to fit regular through-hulls and the output end is NPT threads to fit standard component parts. The details from Groco are here :

http://www.groco.net/CD-07/GROCO%20CAT/ ... 4-2007.htm

I haven't installed the unit yet but the estimated total height (including the handle on top of the ball valve) should be around 4.5" in the 1" size.

George

-

George ( C&C 40 )

- Skilled Systems Installer

- Posts: 254

- Joined: Thu Jan 06, 2005 12:39 pm

- Location: Williamsburg, VA

Hi John,

I assembled one today. With the ball valve on top, like in the picture Tim posted except screwed down tight, the assembled unit looks exactly like a very heavy bronze flanged and through-bolted seacock - especially when the flanged adapter is matched to one of the heavy duty Groco ball valves and through-hulls. It looks like I could balance my car on it without any possibility of the unit breaking.

In my setup, the flanged adapter is caped by a heavy duty bronze "street elle" and the ball valve is screwed into the elle. This puts the ball valve parallel to the bottom of the bilge and off to one side of the flanged adapter. In this setup the handle of the ball valve swings parallel to the bottom of the bilge so very little vertical height is needed - which is why I'm doing it. This setup is not as strong because weight applied out on the far end of the ball valve levers a fair bit of force on the "street elle". It's a much stronger setup than what is currently on my boat but not as strong as a regular seacock. It still looks like it could handle 500 lbs. of force though. However, a very simple solution occured to me as I was fitting the units in my bilge. A 1/2" thick piece of plastic wedged under the ball valve eliminated any possibility of leverage on the "elle" and the finished structure is once again something I could park a car on.

George

I assembled one today. With the ball valve on top, like in the picture Tim posted except screwed down tight, the assembled unit looks exactly like a very heavy bronze flanged and through-bolted seacock - especially when the flanged adapter is matched to one of the heavy duty Groco ball valves and through-hulls. It looks like I could balance my car on it without any possibility of the unit breaking.

In my setup, the flanged adapter is caped by a heavy duty bronze "street elle" and the ball valve is screwed into the elle. This puts the ball valve parallel to the bottom of the bilge and off to one side of the flanged adapter. In this setup the handle of the ball valve swings parallel to the bottom of the bilge so very little vertical height is needed - which is why I'm doing it. This setup is not as strong because weight applied out on the far end of the ball valve levers a fair bit of force on the "street elle". It's a much stronger setup than what is currently on my boat but not as strong as a regular seacock. It still looks like it could handle 500 lbs. of force though. However, a very simple solution occured to me as I was fitting the units in my bilge. A 1/2" thick piece of plastic wedged under the ball valve eliminated any possibility of leverage on the "elle" and the finished structure is once again something I could park a car on.

George

-

Figment

- Damned Because It's All Connected

- Posts: 2846

- Joined: Tue Apr 08, 2003 9:32 am

- Boat Name: Triton

- Boat Type: Grand Banks 42

- Location: L.I. Sound

For those who've installed the Forespar 93 units, what did you use as a tool for inserting the thru-hull? The forespar thru-hull has female notches, not male tabs, so the Groco and Buck-Algonquin tools won't work.

It wouldn't be the first time I've had to "make" a tool, of course, but I'd love to hear about how you guys reinvented this particular wheel.

It wouldn't be the first time I've had to "make" a tool, of course, but I'd love to hear about how you guys reinvented this particular wheel.

-

bcooke

- Master of the Arcane

- Posts: 2272

- Joined: Sat Oct 04, 2003 10:55 pm

- Boat Name: Jenny

- Boat Type: 1966 Pearson Triton

- Location: Rowley, MA

- Contact:

I was able to hand screw the fitting most of the way in and then I .. er.... stuck a screwdriver in the slot and applied pressure via my hammer. Not the best way I know. I went looking for a special tool once but didn't find it and figured I had only 4-5 thru-hulls to put in total so I didn't search too hard. I also have a brand new Groco tool that I haven't had the chance to use since I have gone strictly Forespar to date.

-Britton

-Britton

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

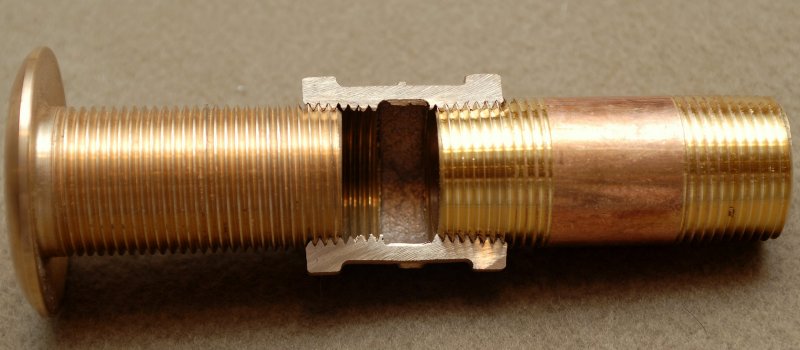

here's how it looks.

Tim wrote: Beware that most through hull fitting threads are likely to be straight thread, not tapered; a lot of the standard pipe fittings have tapered threads and won't thread down sufficiently before binding. This may make your installation more of a challenge than you hoped for! I've seen a lot of straight ball valves perched on top of non-tapered threads with only a few threads truly engaged--not ideal.

Assuming you can find a straight-threaded fitting, you can use a bronze 90? directly on the through hull thread, onto which you can then thread your new ball valve. You'll need non-tapered female threads on one end, and tapered male threads on the other to fit into your straight ball valve. Obviously, the fewer fittings you can use, the stronger and more waterproof the overall setup is going to be.

Tim,

I know this thread is old but I still thought I'd add to your very good points with the picture beow to support what you describe.

A guy on another forum challenged the idea that mismatching threads was OK because "so many do it" so last night I made a cut away view to show why using two different thread types is not such a good idea. While many boat owners screw NPT threaded valves directly onto NPS threaded through-hull fittings it's clearly not a logical idea or even safe as the photo below clearly shows.

To do this I basically used a bronze nipple, or threaded pipe, with standard plumbing threads of NPT (National Pipe Tapered) and a bronze coupling also the industry standard of NPT thread.

I cut the bronze coupling almost in half, for a cut away view, so I could thread the NPT bronze nipple into one side and an NPS through-hull fiting into the other. I then sprayed each with a McLube, to reduce friction but save the picture quality, and threaded both the NPT nipple and the NPS through hull into the cut-a-way bronze coupling by hand and until I had an equal resistance.

The results even surprised me! As you can clearly see the NPT nipple threaded into the NPT coupling a LOT further than did the NPS through-hull. If you were to take a wrench to both you might get one more turn at best out of the NPS through hull but you may still get two or three full turns out of the NPT nipple.

If you look very closely at the picture you can also see the outer-most threads of the through hull are already NOT fitting tightly against the female threads of the coupling and the inner-most threads are quite tight or virtually bottomed out...!!! The square peg evidently does NOT fit a round hole..!

This coupling represents the threads of an in-line valve. Most ALL ball valves or gate valves have NPT or tapered threads and most all through hulls have NPS or straight threads a clear mismatch.

Sticking a ball valve directly onto a through hull gives you about three or four threads between sinking and floating so I can't with a good conscience recommend anyone actually do it. You are spot on suggesting the use of proper seacocks with bolted flanges..!!

I would have cut away an actual ball valve but I don't have a machine shop. The coupling represents and has the same exact NPT female threads as an in-line valve of either the gate or ball type...

- Tim

- Shipwright Extraordinaire

- Posts: 5708

- Joined: Tue Apr 01, 2003 6:39 pm

- Boat Name: Glissando

- Boat Type: Pearson Triton

- Location: Whitefield, ME

- Contact:

Some comments are so entirely foolish that it's not even worth responding in the way they richly deserve.acoustic wrote:A guy on another forum challenged the idea that mismatching threads was OK because "so many do it"

Thanks for your cutaway photo, which ought to be quite illustrative to anyone having trouble understanding why the thread style makes a difference.

---------------------------------------------------

Forum Founder--No Longer Participating

Forum Founder--No Longer Participating

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

Believe it or not..

Believe it or not Tim even with a photo there are a few out there still arguing that it's safe and even going so far to suggest re-cutting the threads on a thru-hull fitting to NPT..?? The lengths to which some will go to save a penny is rather funny..!

-

CharlieJ

- Wood Whisperer

- Posts: 649

- Joined: Fri Aug 19, 2005 7:42 pm

- Location: South coast of Texas, Matagorda Bay

Acoustic- no, it isn't funny. It's absurd.

It's as absurd as someone buying a brand new boat, then squawking about paying for decent anchors. Or dock lines.

And it's things like that that drive serious boat repair people ( Like me) up the wall when we run into it, or have to argue a customer OUT of doing it.

It's as absurd as someone buying a brand new boat, then squawking about paying for decent anchors. Or dock lines.

And it's things like that that drive serious boat repair people ( Like me) up the wall when we run into it, or have to argue a customer OUT of doing it.

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

I though you guys would find these measurements I took interesting:

Total thickness of a 1" Apollo bronze through hull = 2.99mm

Now subtract the depth of the treads cut into it @ 1.45mm deep

2.99mm minus 1.45mm is 1.54mm nominal wall thickness for this 1" thru-hull

Yes this Penny is actually thicker than the cross section of the 1" thru-hull!

Not a lot of meat between your boat and the bottom of the ocean!

I have a full batch of informative photos here:http://www.pbase.com/mainecruising/seacock_primer

Total thickness of a 1" Apollo bronze through hull = 2.99mm

Now subtract the depth of the treads cut into it @ 1.45mm deep

2.99mm minus 1.45mm is 1.54mm nominal wall thickness for this 1" thru-hull

Yes this Penny is actually thicker than the cross section of the 1" thru-hull!

Not a lot of meat between your boat and the bottom of the ocean!

I have a full batch of informative photos here:http://www.pbase.com/mainecruising/seacock_primer

-

Quetzalsailor

- Master of the Arcane

- Posts: 1100

- Joined: Fri Aug 26, 2005 9:53 am

- Boat Name: Quetzal

- Boat Type: LeComte North East 38

- Location: Philadelphia, PA

These last several posts tell you why proper seacocks have flanges and why you use 'em to bolt it into the boat. Lots of bronze to corrode, and you have to loose all three bolts and the throughhull before it come off. With the bolts, the throughhull fitting is just there for decoration, structurally (until you loose the bolts).

This little detail is gonna' cost me over $1500.00 before I go sailing again. The PO left me with a 1" sink drain/head intake inline ball valve mounted on a throughhull w/nut. Every time I cycled that valve I wondered if it was coming off in my hand. I've had the mast pulled which lets me imagine that I've got room enough to dissassemble the cabinet and to work under the sink.

Forespar/Marelon swears that their seacocks need not be bolted since they won't corrode. Then they give you a long song and dance about how you're supposed to lubricate them every 6 months... to keep them from breaking off in your hand.

This little detail is gonna' cost me over $1500.00 before I go sailing again. The PO left me with a 1" sink drain/head intake inline ball valve mounted on a throughhull w/nut. Every time I cycled that valve I wondered if it was coming off in my hand. I've had the mast pulled which lets me imagine that I've got room enough to dissassemble the cabinet and to work under the sink.

Forespar/Marelon swears that their seacocks need not be bolted since they won't corrode. Then they give you a long song and dance about how you're supposed to lubricate them every 6 months... to keep them from breaking off in your hand.

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

Quetzal

Sounds like what happened to me & why I'm no longer comfortable using them:

-

Quetzalsailor

- Master of the Arcane

- Posts: 1100

- Joined: Fri Aug 26, 2005 9:53 am

- Boat Name: Quetzal

- Boat Type: LeComte North East 38

- Location: Philadelphia, PA

Here's their catalog: http://www.forespar.com/onlineCatalog/2 ... atalog.pdf

I'm reasonably (98.24%) certain that they say you don't bolt them in; the holes are not drilled through the relatively small base. (Tried to find the instructions online, but failed.) I see that they now offer flange-based seacocks, which I don't think they did 2 years ago (or I would have bought one!).

Being just a little stubborn, I had wished to use a bronze seacock but none was 'low rise' enough to fit under the cockpit and to accept the connections from the drains at either side. The original massive bronze plug type had fittings molded into it for that purpose.

Forespar is really ginger about their weak handles and valve stems. I had discussed with their engineer my plan to put a 'four bar link' and a handle up high so that I would not have to lazarette-dive to get within reach of the seacock to cycle it. They absolutely recoiled at the idea and told me that their guarantee would not cover it.

I'm reasonably (98.24%) certain that they say you don't bolt them in; the holes are not drilled through the relatively small base. (Tried to find the instructions online, but failed.) I see that they now offer flange-based seacocks, which I don't think they did 2 years ago (or I would have bought one!).

Being just a little stubborn, I had wished to use a bronze seacock but none was 'low rise' enough to fit under the cockpit and to accept the connections from the drains at either side. The original massive bronze plug type had fittings molded into it for that purpose.

Forespar is really ginger about their weak handles and valve stems. I had discussed with their engineer my plan to put a 'four bar link' and a handle up high so that I would not have to lazarette-dive to get within reach of the seacock to cycle it. They absolutely recoiled at the idea and told me that their guarantee would not cover it.

-

Quetzalsailor

- Master of the Arcane

- Posts: 1100

- Joined: Fri Aug 26, 2005 9:53 am

- Boat Name: Quetzal

- Boat Type: LeComte North East 38

- Location: Philadelphia, PA

I was just 'called down' by a respected correspondent on this site:

"I didn't see anything in that catalog to suggest that the seacocks need not be bolted. There is a photo of a series 93 unit installed without bolts, but that's about it. Certainly nothing that connects the issue of corrosion with the issue of through-bolting.

"Flanged base marelon seacocks have been available for at least ten years, probably more like fifteen. I think Practical Sailor used them on a test boat in 1990 or 1992, but it may have been a later installation on a boat made in 90 or 92, I'm not certain.

"I'm not the "Forum Truth Cop" or anything, but I think you should be more careful about what you post. The online boating community has enough partial information as it is."

No doubt he's right, however, I was all over the Marelon site a couple years ago, spoke with them in person, bought what I bought after discussing it with them. I'll try to dig out the instructions and see. They wrote that its not necessary to bolt 'em in. The holes are not bored all the way through the base. They brag about just how strong that little 45 degree flange on the throughhull is. For my 1 1/2" seacock, there were, I think, four preparations for 1/4" bolts which are much closer to the bore and smaller in dia than those of flanged seacocks.

"I didn't see anything in that catalog to suggest that the seacocks need not be bolted. There is a photo of a series 93 unit installed without bolts, but that's about it. Certainly nothing that connects the issue of corrosion with the issue of through-bolting.

"Flanged base marelon seacocks have been available for at least ten years, probably more like fifteen. I think Practical Sailor used them on a test boat in 1990 or 1992, but it may have been a later installation on a boat made in 90 or 92, I'm not certain.

"I'm not the "Forum Truth Cop" or anything, but I think you should be more careful about what you post. The online boating community has enough partial information as it is."

No doubt he's right, however, I was all over the Marelon site a couple years ago, spoke with them in person, bought what I bought after discussing it with them. I'll try to dig out the instructions and see. They wrote that its not necessary to bolt 'em in. The holes are not bored all the way through the base. They brag about just how strong that little 45 degree flange on the throughhull is. For my 1 1/2" seacock, there were, I think, four preparations for 1/4" bolts which are much closer to the bore and smaller in dia than those of flanged seacocks.

-

bcooke

- Master of the Arcane

- Posts: 2272

- Joined: Sat Oct 04, 2003 10:55 pm

- Boat Name: Jenny

- Boat Type: 1966 Pearson Triton

- Location: Rowley, MA

- Contact:

Nothing on this or any other internet forum is anything but personal opinions. Everyone needs to make up their own minds about what we read here. We all have a right to our own opinions as long as we aren't disparaging someone else.

In my own experience, I installed two of the Marelon 1.5" seacocks and a 0.75" seacock four years ago. Another three seacocks installed last year. No problems so far.

On the flanged units I bought, the mounting holes were bored all the way through. I bolted in my seacocks with a 0.750" thick plywood backing pad that was about 2 inches in diameter wider than the actual seacock flange area. Will they aborb a 500 pound impact from the side? I couldn't tell you. I can say that I am not too worried about them.

-Britton

In my own experience, I installed two of the Marelon 1.5" seacocks and a 0.75" seacock four years ago. Another three seacocks installed last year. No problems so far.

On the flanged units I bought, the mounting holes were bored all the way through. I bolted in my seacocks with a 0.750" thick plywood backing pad that was about 2 inches in diameter wider than the actual seacock flange area. Will they aborb a 500 pound impact from the side? I couldn't tell you. I can say that I am not too worried about them.

-Britton

-

Maine Sail

- Skilled Systems Installer

- Posts: 243

- Joined: Fri Feb 24, 2006 10:47 am

- Location: Casco Bay

- Contact:

For tight spaces..

For tight spaces these flanged adapters from Groco are nice alternative to a traditional seacock. The nice thing is if your valve fails or freezes up you simply unscrew it and thread on a new one leaving the thru-hull, through bolts and sealant untouched. They are also designed so the top threads are NPT and the thru-hull side are NPS so you have perfectly matching threads.

While I don't like using a street elbow right off the flange I had no choice as a traditional seacock would not fit in this particular situation.

While I don't like using a street elbow right off the flange I had no choice as a traditional seacock would not fit in this particular situation.

- Peter

- Boat Obsession Medal Finalist

- Posts: 580

- Joined: Mon Nov 15, 2004 11:23 pm

- Boat Name: Pagan

- Boat Type: Albin Ballad 30

- Location: Pedder Bay (Victoria), BC, Canada

- Contact:

That's especially handy, too, when Groco issues a recall on the valves ... makes them a lot easier to replace!acoustic wrote:The nice thing is if your valve fails or freezes up you simply unscrew it and thread on a new one leaving the thru-hull, through bolts and sealant untouched.

I see you have the ones with the non-stainless shafts, so you are OK. I'm still waiting to hear back from them on my suggestion they replace the defective ones with their higher quality valves.

We shall see.

-

Tim Mertinooke

- Skilled Systems Installer

- Posts: 200

- Joined: Wed Jan 11, 2006 12:50 am

- Location: Massachusetts

- Contact:

I finally had time to closely inspect the existing seacocks on my Fuji and was pleasantly surprised to find they were all bronze with tapered plugs and in great shape. There are a total of six Wilcox Crittendens and one Spartan. Three of the Wilcox Crittendens are 1.5"; one for the galley sink, the other two for the cockpit scuppers. There are two WC's in the Head, one 3/4" for the toilet raw water intake, and another 3/4" for the sink drain. The last WC is a 3/4" for the engine raw water intake. I removed this one completely including the strainer and mushroom fitting because the plywood backing had corroded and there was back and forth movement when I rocked the hose. There is also no true base for this particular seacock, it is screwed onto the mushroom fitting. There was only a retaining nut against the plywood backing plate screwed on to the mushroom fitting. I hope that the Groco triangular base Acoustic posted earlier will fit, as this would be an easy solution to stiffening up that area when I put the seacock back on. The 1.5" Spartan, which is for the head discharge, was the only one that gave me any trouble. The tapered plug did not just come out like all the others, but had to be persuaded with a plastic mallet after removing the D-nut, plate, and retaining nut. All seven plugs were degreased, sanded with #220 lightly, then regreased and reassembled. Now they all work smoothly.

These were out of five of the WC's.

The Spartan after reassembly.

These were out of five of the WC's.

The Spartan after reassembly.

Fuji 32 Ketch "Excalibur"

-

Tim Mertinooke

- Skilled Systems Installer

- Posts: 200

- Joined: Wed Jan 11, 2006 12:50 am

- Location: Massachusetts

- Contact:

I can verify that no smurfs (smurves?) were hurt during the production of the grease seen in previous photos.

My dad swears by this stuff and calls it "farm grease". I don't know what brand it is, but will check when I head out that way the end of this month. He's an excessive compulsive greaser, so what he recommends, I use. We'll see how it holds up as I will be lapping them again this fall. He greases his folding prop with it every year and after haulout, it is still well greased. He averages about 350NM a season. Tenacious stuff!

My dad swears by this stuff and calls it "farm grease". I don't know what brand it is, but will check when I head out that way the end of this month. He's an excessive compulsive greaser, so what he recommends, I use. We'll see how it holds up as I will be lapping them again this fall. He greases his folding prop with it every year and after haulout, it is still well greased. He averages about 350NM a season. Tenacious stuff!

Fuji 32 Ketch "Excalibur"